| Museum News 2010 |

|

(Back to Archive News Page) |

|

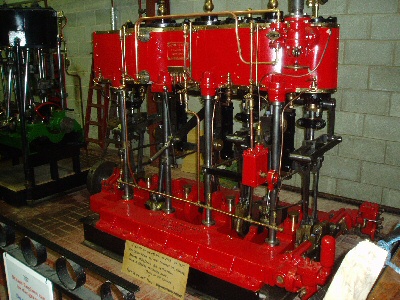

January 2010 Plenty Marine Engine The inverted, vertical, triple marine engine, built in 1925 by Plenty & Son, Newbury. This engine has now been fully restored to steaming condition. Just before Christmas it was moved to its permanent postion in the museum, between the Fleming & Ferguson and Sissons marine engines. It now awaits a steam and exhaust connection. |

| The splendid looking Plenty marine engine, recently restored. |

|

|

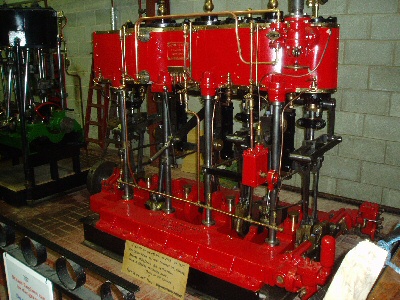

Thursday 26th August 2010 Clapham Road Beam Engine In May 2009 the International Stationary Steam Engine Society informed the museum that a beam engine was looking for a new place to rest. The beam engine was on static display in the grounds of Bedford College and had been donated to the College in 1965 from the Clapham Road Pumping Station, Bedford. |

| Clapham Road Beam Engine as displayed in the car park of Bedford College. |

|

Negotiations took place and as a result a team from Markham Grange travelled down to assess the difficult task of dismantling and transporting it back to Doncaster. One important question came to light - since about a quarter of the flywheel was not visible above ground 'was it complete or had it been cut off?' To answer this the College removed the concrete around the flywheel and found it was intact, although somewhat corroded. Soon afterwards the team started to remove some of the the relatively smaller, lighter parts, i.e. eccentric rods and pump rods, and transport them to the museum. To transport the engine on a low loader, it would have to be separated into several manageable components. The next few trips were taken up in freeing off rusted nuts, bolts, cotters, and bearing caps etc. 45 years outside had taken its toll. A strong frame, made from RSJ's, was designd and constructed so that the 16 ft. diameter flywheel could be supported at an angle, to reduce the height for transportation and to ensure that it would go under the roller door at the museum. When all was ready a crane was hired to load the low loader with the three main components - the flywheel complete with crankshaft and crank; the beam with its bearings etc.; the cylinders, columns and bedplate, being the heaviest lump. To complicate matters, there was a large crack in the bedplate, this had to be supported by a temporary steel splint strapped to the area of the crack. Thankfully everything fitted nicely onto the deck of the low loader. Friday 27th August

|

| The beam engine secured on low loader. |

|

| Lifting the beam. |

| Manipulating the beam into the museum. |

|

| Lifting the flywheel. The crane driver was a bit concerned with proximity of the overhead cables. |

|

Flywheel, on its frame, ready to enter the museum.

The ground, at the roller door entrance, had to be excavated to keep the frame level. |

| Lifting the bedplate with cylinder block and columns. |

|

| Inching the cylinders etc. into the museum. |

| Only just enough headroom. |

|

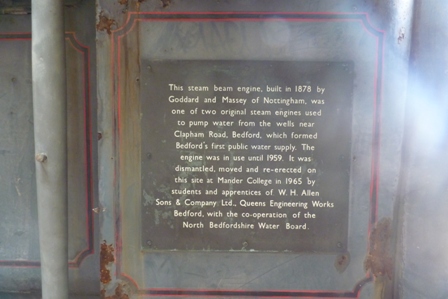

| Plaque on the side of the cylinders. |

|

August - November 2010 Clapham Road Beam Engine - Update Our crane has a limit of 7.5 tons and the combined weight of bedplate/columns and cylinders was in excess of

this, so the first task was to remove the cylinders to lighten the load. Before this could happen all connecting

pipes, valve chests, valves etc. had to be removed. Cylinder covers/glands were removed to reveal the condition of

the cylinder bores, which were, surprisingly, quite good, considering the amount of time they had spent outdoors.

Attention then turned to the beam - the parallel motion links and rods were removed and stored to one side. It enabled the beam to rest on its bearing pedestals. This again was not an easy operation, since most of the motion pivot bearings were well and truly stuck to their relative pins. The arduous task of removing rust and paint from the flywheel, (to get down to bare metal), has started and is ongoing. |

|

HP and LP cylinders - the valve faces shown are in good condition. |

| Removing HP piston (19.5ins diameter) from its cylinder. |

|

|

The beam (over 17ft long) shown with parallel motion links and rods removed. |

|

|