| Museum News 2007 |

|

(Back to Archive News Page) |

|

January to May 2007 In January the Museum was closed because of work being done to the extension. There was a period of time when the existing building was insecure so a decision was made to remove all brass and copper items from the engines and store them in a safe place.

|

|

Museum extension with new roller door. |

|

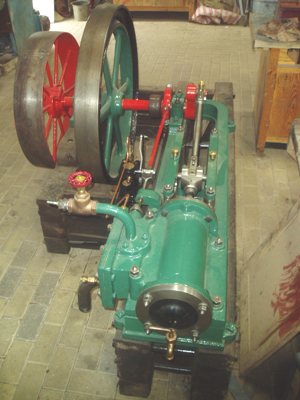

Horizontal Engine on loan from Bradford Industrial Museum It was reported in Museum News 2005 that this engine had been removed from its wooden frame, made from railway sleepers, prior to it being stripped down. The project has now been taken over by another volunteer and the engine has been completely rebuilt and looks well with its new paintwork. However the decision has been made to re-mount it back onto the wooden frame. It now awaits a permanent position in the Museum. |

| Rebuilt horizontal engine on loan from Bradford Industrial Museum |

|

|

Thornewill & Warham Engine For some time now it has been difficult to stop steam from leaking past the valve rod glands on the left hand engine (looking from the cylinder end). The reason for this was excessive wear to the valve rods where they pass through the glands. The only remedy was to renew the rods themselves, which would then require new brass bushes fo the glands and valve chest.

Work started at the end of 2006 by removing the piston from the RH engine and removing the slide and expansion valves and rods from the LH engine.

|

|

One of the valve rods showing the substantial wear to part of the diameter |

|

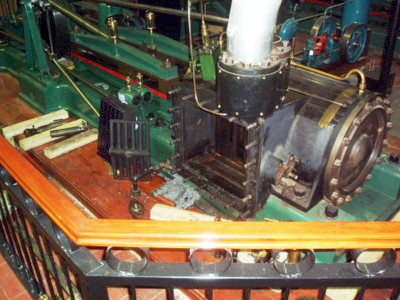

The dismantled LH engine valve chest.

To the left of the valve chest, is the slotted expansion valve, which is resting on the main slide valve. |

|

|

New Arrival, 2nd May 2007 Tandem Compound Horizontal Mill Engine, built by Marsden's Engines Ltd in 1907 - name 'Rhoda'. The Museum took delivery of the HP and LP cylinders belonging to this engine, which is being dismantled at Runtlings Mill, Ossett, West Yorkshire. Once all the parts have arrived work will start on restoring/re-building the engine in the new museum extension.

|

|

Unloading the cylinders and bed plate. |

|

June to November Thornewill & Warham Engine - repairs to the left hand engine were completed in July and is now back in steam. Similar repairs are ongoing on the right hand engine, ie. new valve rods required to replace the worn out ones. Rhoda Mill Engine - the remaining parts of the engine were delivered to the museum during Monday 17th September. Work has started on cleaning and examining the many parts to this engine. |

| Some parts of 'Rhoda' have been cleaned and painted with red primer. |

|

|

Reliant - Steam Paddle Tug The original steam steering gear and engine belonging to 'Reliant' has been brought in from the outside store. It is a Combined Steam and Hand Type, vertical, duplex steering gear, built by Alley & MacLellan 'Sentinel', No. 2277. Bore 4ins. and stroke 5 ins.

|

|

The partly restored steering gear from the steam paddle tug 'Reliant' |

|

Small engine uncovered. Whilst having a clear out in one of the indoor storage areas, a small, horizontal, single cylinder steam engine was uncovered. The makers name, cast on the valve steam chest cover, is simply 'Farmer Bros'.

|

|

|

January 2008

Work on this engine has progressed well. The valve gear, which incorporates an interesting reversing system, has been completely overhauled.

Cylinder pistons, connecting rods, crankshaft components etc. have been refurbished and reassembled with all bearings and slides adjusted to working conditions.

A cylinder pre-heating system has been designed and fitted, which it is hoped, will keep condensate down to a minimum whilst the engine is stationary.

|

|

First test run, under steam, of the 'Reliant' steering engine |